Bryson Drilling’s ‘Ace’ team: Defeating extreme weather and harsh terrain to complete a challenging multi-client project

Coring Magazine Feature Praises Bryson Drilling Success:

JUNE 7, 2021

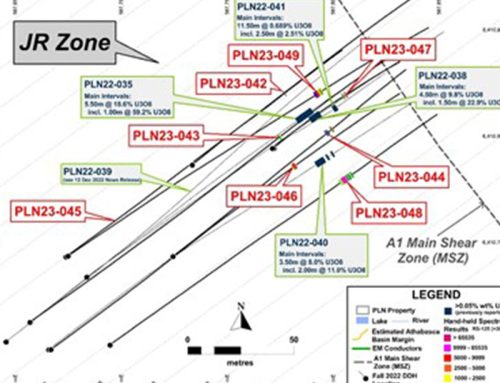

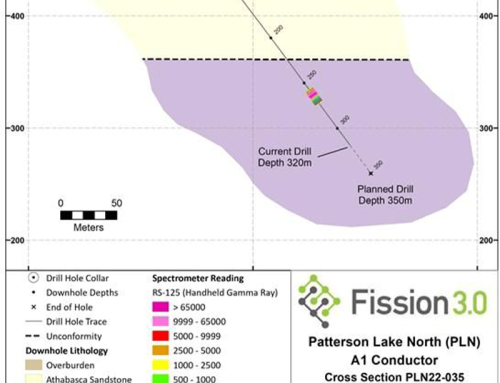

This winter season Bryson Drilling (Bryson) was awarded a multi-client project for Terralogic Exploration Inc. on behalf of SKRR Exploration/ Taiga Gold Corp. on the remote Irving/ Leland property in Saskatchewan, Canada, located about 60 km (37 mi) away from the nearest access point. The Irving/Leland Project is a large land package covering more than 23 500 hectares strategically located within 10 to 20 km (6 – 12 mi) of SSR Mining’s very successful Seabee Gold Mine operation, the largest orogenic gold deposit in Saskatchewan.

Irving/Leland is located approximately 100 km (62 mi) North of La Ronge at a heading of 58° Northeast. The location required significant preparation and planning to ensure a successful project completion. Even though the majority of Bryson’s exploration is in the Uranium industry, in this particular project gold was the main commodity we were looking for, with several other base metals including copper and zinc.

We sent our ‘Ace’ team of eight people to the site – three drillers, three helpers, one foreman and an eight man – a local indigenous worker, who was hired to work on the project. They were successful due to their wealth of experience and commitment to seeing the project through despite the extremely challenging conditions.

The team had to endure several weeks of extreme temperatures well below freezing. Due to the harsh and challenging environment, the operation required heli- and plane-portable equipment mobilization. The extreme temperatures of -50°C (-58°F) made helicopter and plane runs even more difficult. Therefore, equipment and gear preparation was a key aspect. We used a specially customized modular drill for fly-in areas with packages that weighed less than 1250 lb (567 kg) so it could be moved by the Bell 206 helicopter easily, and yet was powerful enough to drill up to 600 m (1969 ft) of N-size. We also designed our own fully custom modular shacks that were easy to transport with the Bell 206 helicopter and very quick to assemble and take down in order to move with a Single Otter plane.

Working for prolonged periods in such conditions can be perilous and may lead to accidents or even injuries. That’s why we had to adapt our drilling scheduling to three shifts of eight hours, rather than the regular two by twelve to allow our men to rest and stay safe in the cold. The on-site survival shack that we prepared, was equipped with emergency supplies. There were 700 000 BTU of heat to keep the equipment and work area at safe working temperatures, as limited hours of daylight could affect crew changes and resupplying. The water lines also needed heaters and snow packs for insulation.

Due to the remote nature of the project, we performed crew changes by plane and availed ourselves of local accommodations. The limited access to supply chains was also a concern, therefore, local communities and accommodations were utilized as much as possible. Thus we developed relationships with them and helped engage their business and employment. Prior to working on the project, Terralogic Exploration had also undergone extensive consultations with local communities and indigenous bands to ensure any concerns relating to their traditional lands and potential impact were addressed.

Bryson continues to encourage local engagement to create a sustainable future on all lands, while creating the potential for future employment in remote areas and recognizing land use rights.

Despite all difficulties, our team completed a total of 34 holes over 66 operating days accumulating 4605 m (15 108 ft) between three properties with one drill in the period from January to April 2021. Because of our careful preparation and the innovations, the jobs were completed on schedule with zero loss time or environmental impact incidents. Our team’s commitment to safety and quality work was key in meeting these results.

Following this success, our team moved some 130 km (81 mi) away from Leland/Irving to Fathom Minerals Rottenstone property utilizing only two helicopters (B3 & Bell 206) and one Twin Otter ski plane.

About the company

Bryson Drilling was created by three generations of hard-working mineral exploration drillers who passed on the learned knowledge that only experience, time and passion teach. After working in North and South America, Europe, Ecuador, Chile, etc., Bryson officially opened its doors for business to provide surface and specialty drilling services across Canada in 2007. With over 100 years of combined experience, Bryson remains a locally family-owned and operated business based out of Archerwill, Saskatchewan.

Bryson’s headquarters are located on Treaty 6 land. The traditional hunting, traveling and gathering land of the Blackfoot, Cree, Saulteaux, Dene, Dakota and Lakota Sioux Nations and the Homeland of the Metis Nation. Bryson Drilling acknowledges Canada’s colonial history.

Bryson began operations in the Athabasca Basin of the Northern Canadian Shield and has subsequently successfully completed large-scale projects in numerous locations nationwide for some of the industry’s largest companies. Bryson is proud of our earned reputation. Our clients often become repeat clients due to our impressive work ethic, quality control, stewardship of the land and commitment to the environment.

For more information visit: www.brysondrilling.ca

Read more Issue #16 articles:

Read more Issue #16 articles: